Where vehicle production ends and system integration begins

Vehicle system integration is often confused with manufacturing in zero-emission mobility, although these are two different roles with different responsibilities. This is understandable – the vehicle is the visible result. In practice, however, something else is decisive: whether the entire propulsion system will work reliably in a particular operation. And this is where system integration starts.

Why these roles are often mistaken

Vehicle production has clear contours. Design, assembly, workmanship and product repeatability are addressed. However, when it comes to emission-free operation, production alone does not close the issue.

The decisive questions are the ones that come only during real deployment: how the system will behave in operation, how the individual components work together, and whether the whole solution will hold up from both a technical and regulatory perspective.

What does vehicle production typically address

Vehicle production is mainly focused on:

- 🔹 Vehicle design,

- 🔹 production process and processing quality,

- 🔹 product repeatability and stability.

This is a necessary and important part of the whole chain. At the same time, manufacturing does not address all the issues that determine the success of an emission-free solution in practice.

The moment where production is not enough

As the vehicle moves from design to real-world operation, new deciding factors emerge.

For example:

- 🔹 how the drive system behaves in a specific route profile and mode of operation,

- 🔹 how the control systems, traction, battery and fuel cell work together,

- 🔹 what trade-offs are needed for a solution to make sense in a given deployment,

- 🔹 how the whole system fits into the legislative framework.

It is at this point that the distinction between manufacturing and integration breaks down. Technology alone is not enough.

Vehicle system integration as a decision process

Systems integration is not a single step or a one-time intervention. It is a process in which:

- 🔹 proposes the architecture of the whole solution,

- 🔹 verifies the cooperation of individual subsystems,

- 🔹 addresses different operational scenarios,

- 🔹 and the system is gradually fine-tuned for specific uses.

Integration is not about the technology itself, but about how everything works together in a single operation.

Why a system integrator needs partners

Emission-free drives are built on a number of specialized technologies. Therefore, it is natural for an integrator to work with partners and components from a variety of sources.

However, the important thing is that the system integrator:

- 🔹 does not compose solutions randomly,

- 🔹 is responsible for the functionality of the entire system,

- 🔹 manages testing and verification in real-world conditions,

- 🔹 and ensures legislative compliance of the solution.

Partnerships deliver specialized parts. The integrator ensures that everything works together as one.

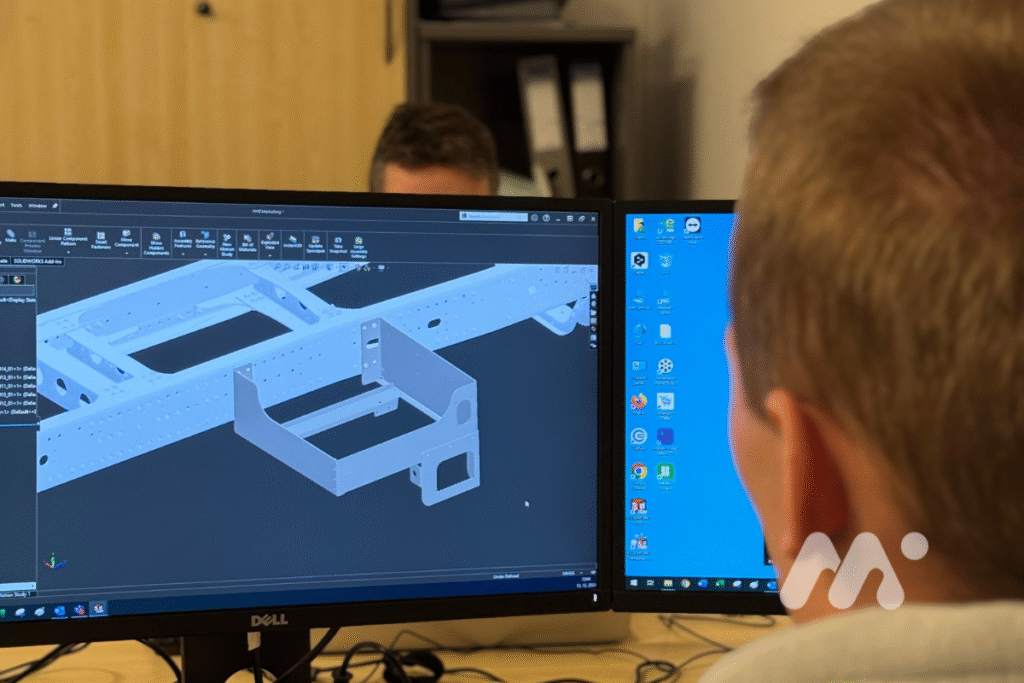

What it means for Mobility & Innovation Production

Mobility & Innovation Production has long been a system integrator for emission-free drives. For each project, we start from the specific operational task and design a tailor-made drive – from the architecture of the solution to its commissioning.

The result is not just a vehicle, but a functional emission-free system ready for real-world conditions.

FAQ

Is system integration the same as component assembly?

No.

Assembly is only part of the process.

Integration means designing and setting up the entire system to

work reliably in a particular operation.

Why does MIP work with partners?

Because emission-free drives use more specialised technologies.

Partnerships enable the selection of suitable components,

with MIP as integrator being responsible for the functionality of the whole.

Why is MIP not a vehicle manufacturer?

Because manufacturing and integration are two different disciplines.

MIP focuses on system solutions,

not on mass production of vehicles.

Recommended articles

- System integrator in mobility: what it means in practice

- Real consumption of H2 vehicles: what influences the result in operation

- Hydrogen tractor: real-life testing (METRANS)