How drive system integration works in practice

The future of mobility is not about one technology, but about the right solutions in the right place.

This is why system integration of drives is a key service that enables transport companies to move to zero-emission transport efficiently, safely and sustainably.

At Mobility & Innovation Production, we are not tied to a single technology. Our goal is to deliver a tailor-made drive that exactly matches the client’s operational needs – whether it is hydrogen drive, electric drive or hybrid drive. How does this process work in practice?

What drive system integration means

Drive system integration is a comprehensive service that combines needs analysis, solution design, component selection and integration, testing, vehicle homologation and commissioning.

It is not just about “fitting the technology”. It is a comprehensive process to ensure that an emission-free vehicle not only works, but also meets legislative standards and the real needs of hauliers.

Step 1 – Client needs analysis

Every fleet is different. Therefore, the first step is always a thorough analysis:

- type of transport (urban, suburban, long-distance, special),

- daily kilometres and route profile,

- performance and weight requirements,

- operating conditions and available infrastructure.

This phase is the basis for selecting the optimal solution that will deliver efficient and reliable emission-free operation.

Step 2 – Customized solution design

Based on the analysis, the optimal technology is proposed: hydrogen drive for long range and fast filling, electric drive for urban transport or hybrid drive for combined conditions.

The result is a tailor-made drive that respects the client’s needs while being ready for future changes – thanks to its modularity, it can be added to or adapted according to the evolution of technology and legislation.

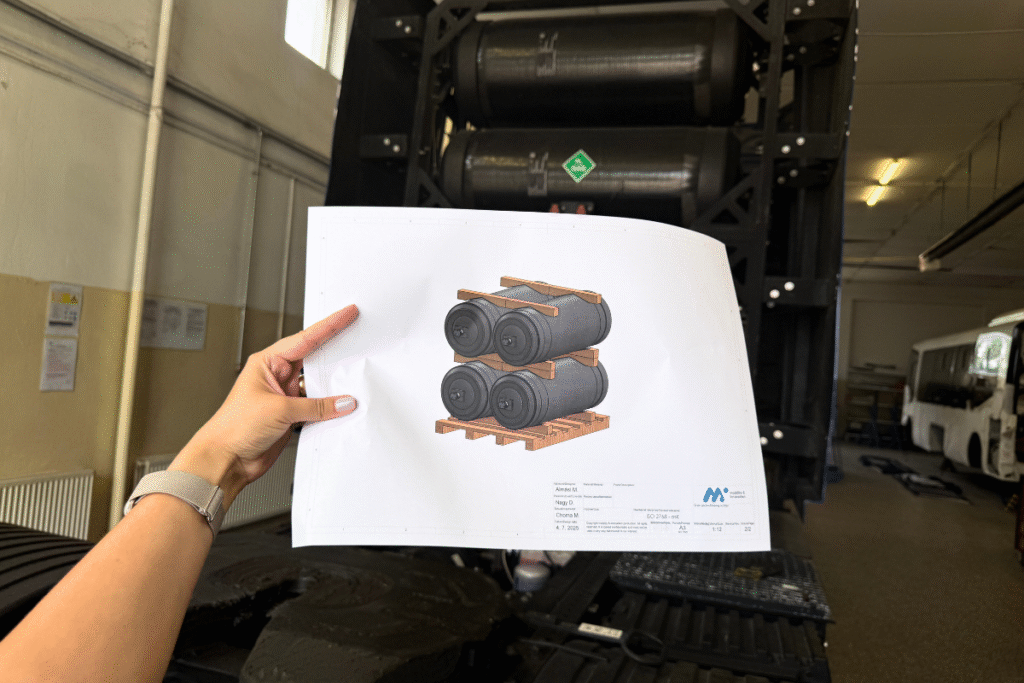

Step 3 – Component integration and development

Choosing the right components is critical.

The following can enter the solution:

- 🔹 Fuel cells,

- 🔹 Traction batteries,

- 🔹 electric motors,

- 🔹 gearboxes,

- 🔹 control systems.

An example is the M&I RH120R hydrogen tractor, where we have integrated a Dana Sumo engine together with a special Eaton 4-speed heavy-duty transmission for the first time in Europe. This combination delivered a power output of 540 kW and a range of 600-750 km per hydrogen fill.

Step 4 – Homologation and testing

Each solution must pass vehicle homologation to the strict standards of the European Union. This means that the vehicle meets all technical, safety and environmental requirements.

In addition to laboratory testing, real-life testing is also crucial. That’s why we test our vehicles with partners such as METRANS to confirm their reliability in practice.

Step 5 – Commissioning and Support

After successful testing, the vehicle is handed over to the client – fully homologated and ready for deployment in the fleet. Training, technical support and long-term service are included.

Our goal is to make the transition to zero-emission transport not a complication for the carrier, but a competitive advantage.

Why system integration is advantageous

- 🔹 Comprehensive turnkey service – from design to operation.

- 🔹 Independence from one supplier – we choose components according to needs, not contracts.

- 🔹 Flexibility and modularity – solutions that can be further developed.

- 🔹 Proven know-how – experience in the development of custom buses and hydrogen propulsion for tractors.

Conclusion

System integration of drives is the way to bring emission-free mobility into practice.

It allows transport operators to get a tailor-made solution – without compromise and with the confidence that the technology will work today and tomorrow.

👉 If you’re looking for a partner who can tailor-make your drive and guide you through the entire process from design to vehicle homologation, we’re ready to be that partner.